Solutions for e-mobility

From individual battery cells to the finished battery pack, from the connector to the complete charging station or from the smallest plastic parts to complex interiors - and exterior parts. With our mechatronic gripping components, we offer you solutions that have been tried and tested in practice. A lot is possible for full performance in all areas of e-mobility.

As a German manufacturer with over 40 years of experience, we produce at climate-neutrally certified locations and supply you with customer-oriented and high-quality products and solutions handling of your products. The modular system enables gripping solutions to be adapted to your product areas and production processes. The properties of our range of services and our mechatronic components include:

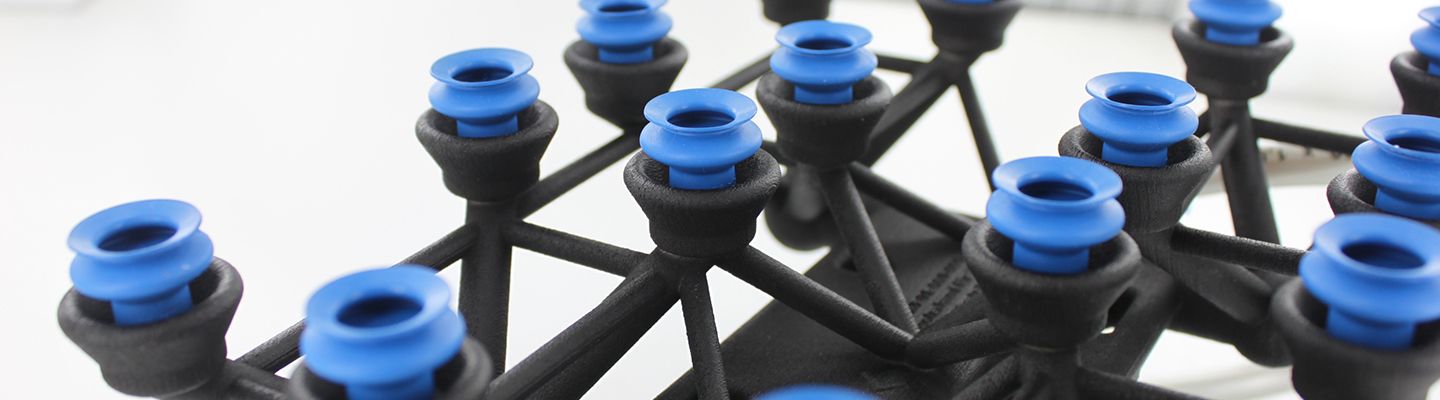

Heat-resistant components

Gripping components and insulators in contact with components with heat-resistant properties enable process-reliable handling of hot materials. Organic sheets or pultruded components can be safely moved, even in heating fields. Heat-resistant grippers, needle grippers or vacuum suction cups make it possible.

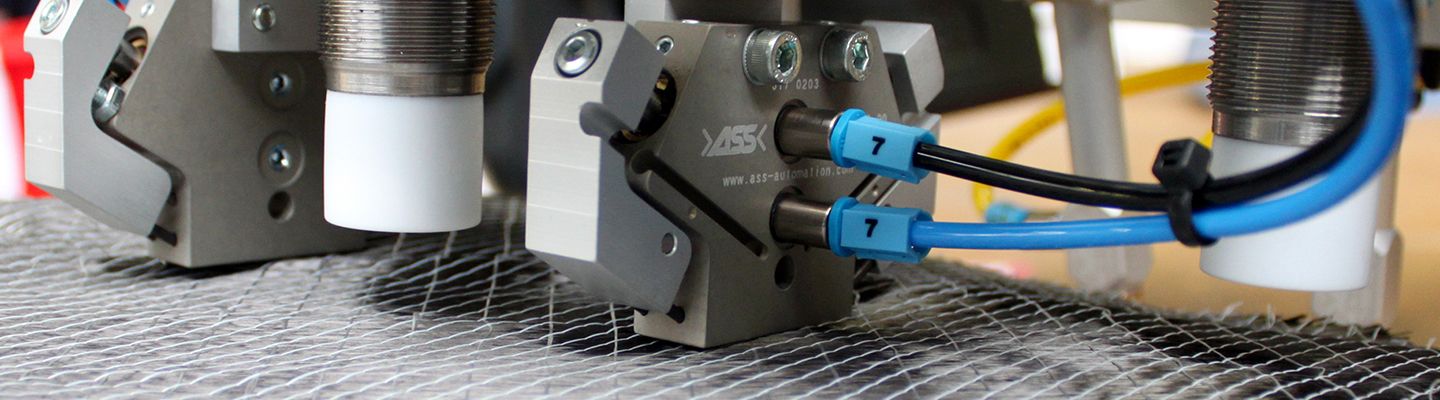

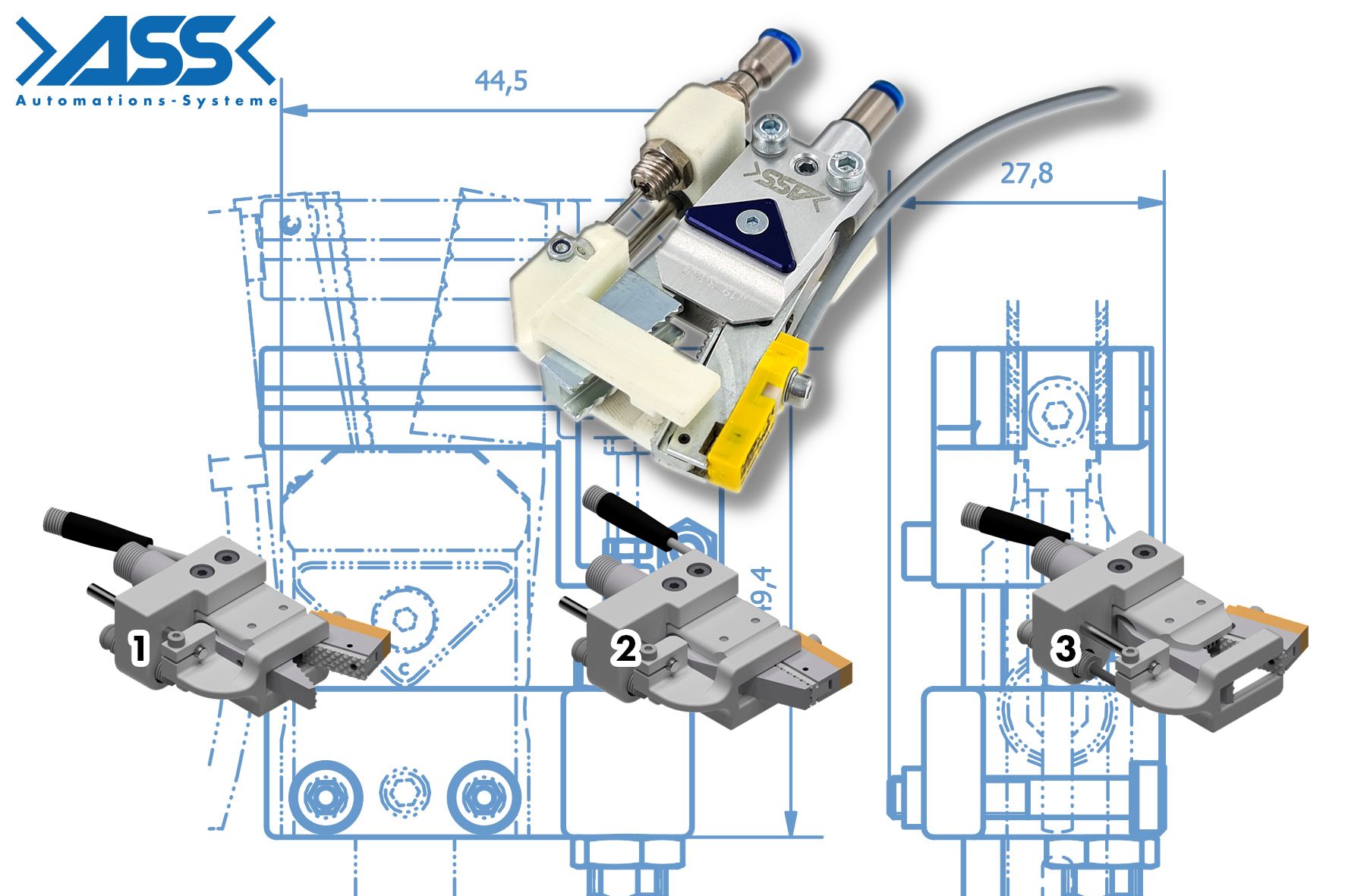

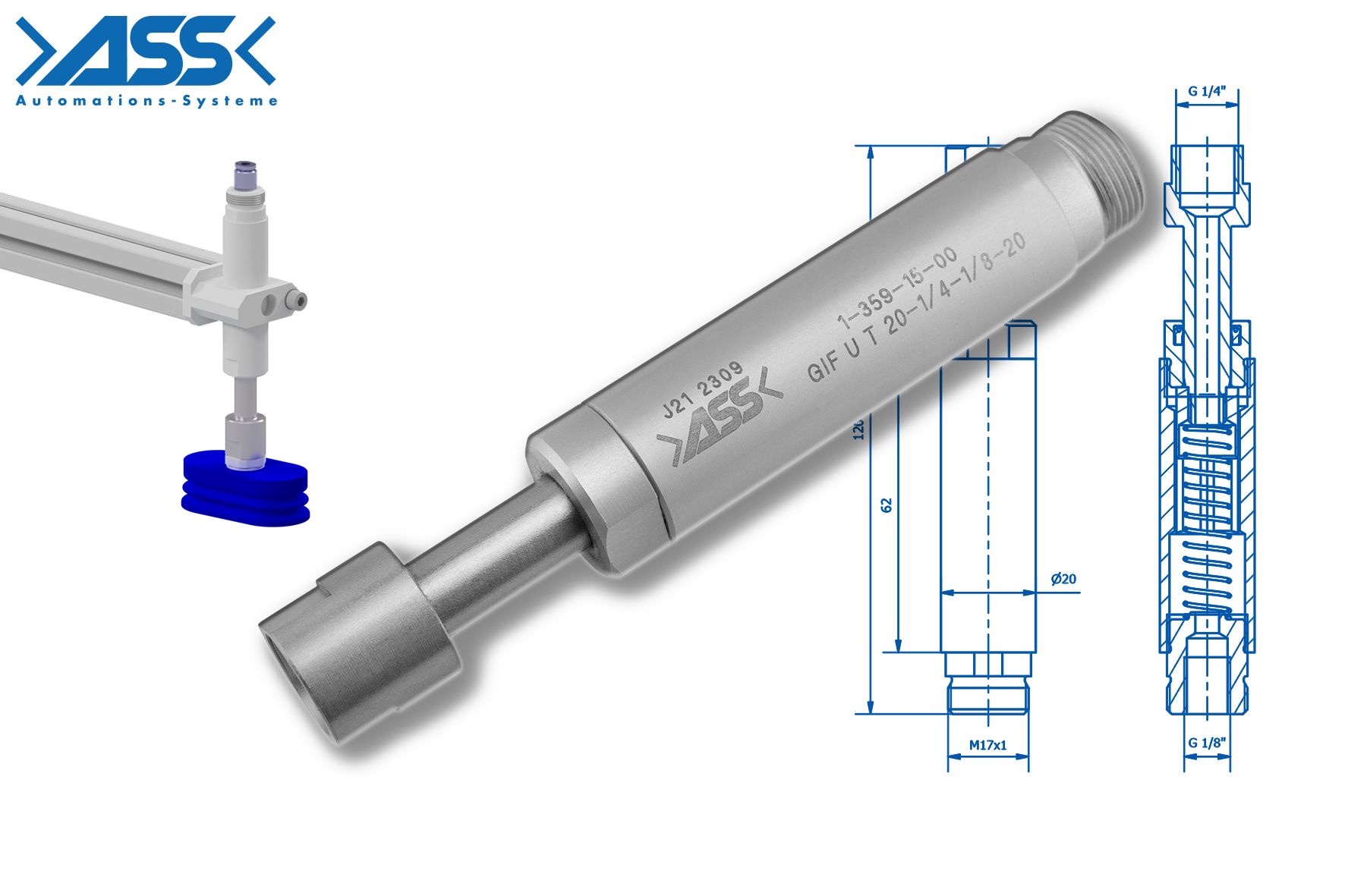

Compact design

Flat components and their possible combinations allow gripping solutions in the smallest of spaces, for example when inserting electronic components, cell modules or cell stacks in battery housings. For example, our pneumatic parallel grippers PGR-P or the non-stick coated needle grippers with combined air connections can be arranged in the smallest of spaces to save space.

Our award-winning and innovative Micro System also stands for smallest parts available.

Lead-free handling

Special coatings and adapted or adjustable force regulations enable parts with sensitive surfaces to be handled. For example, painted or thin-walled parts can be moved safely without restrictions.

In addition to already coated standard components such as gripping tongs or gripping fingers, we use our EP coating to minimize markson the contact surfaces with your workpiece.

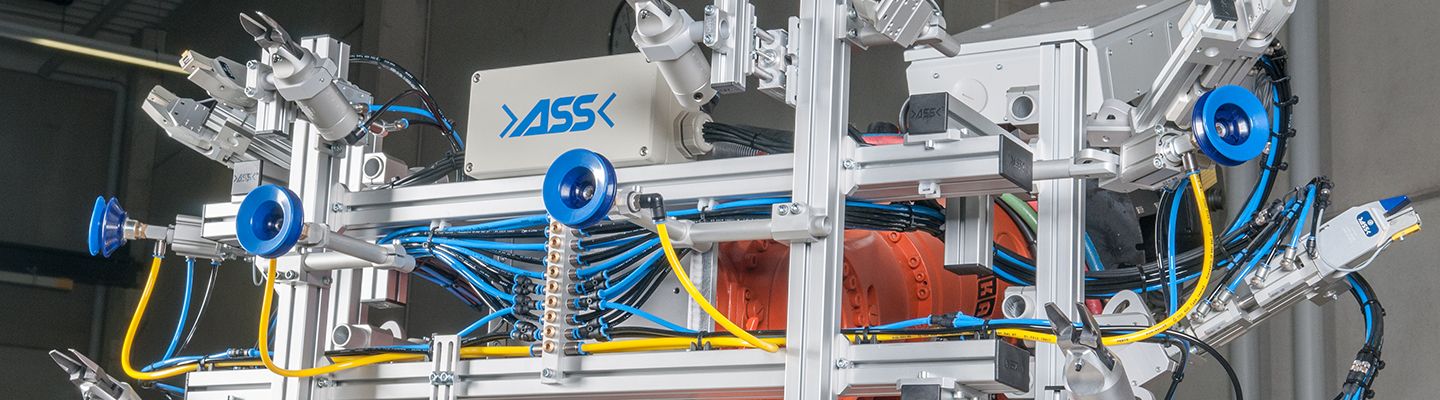

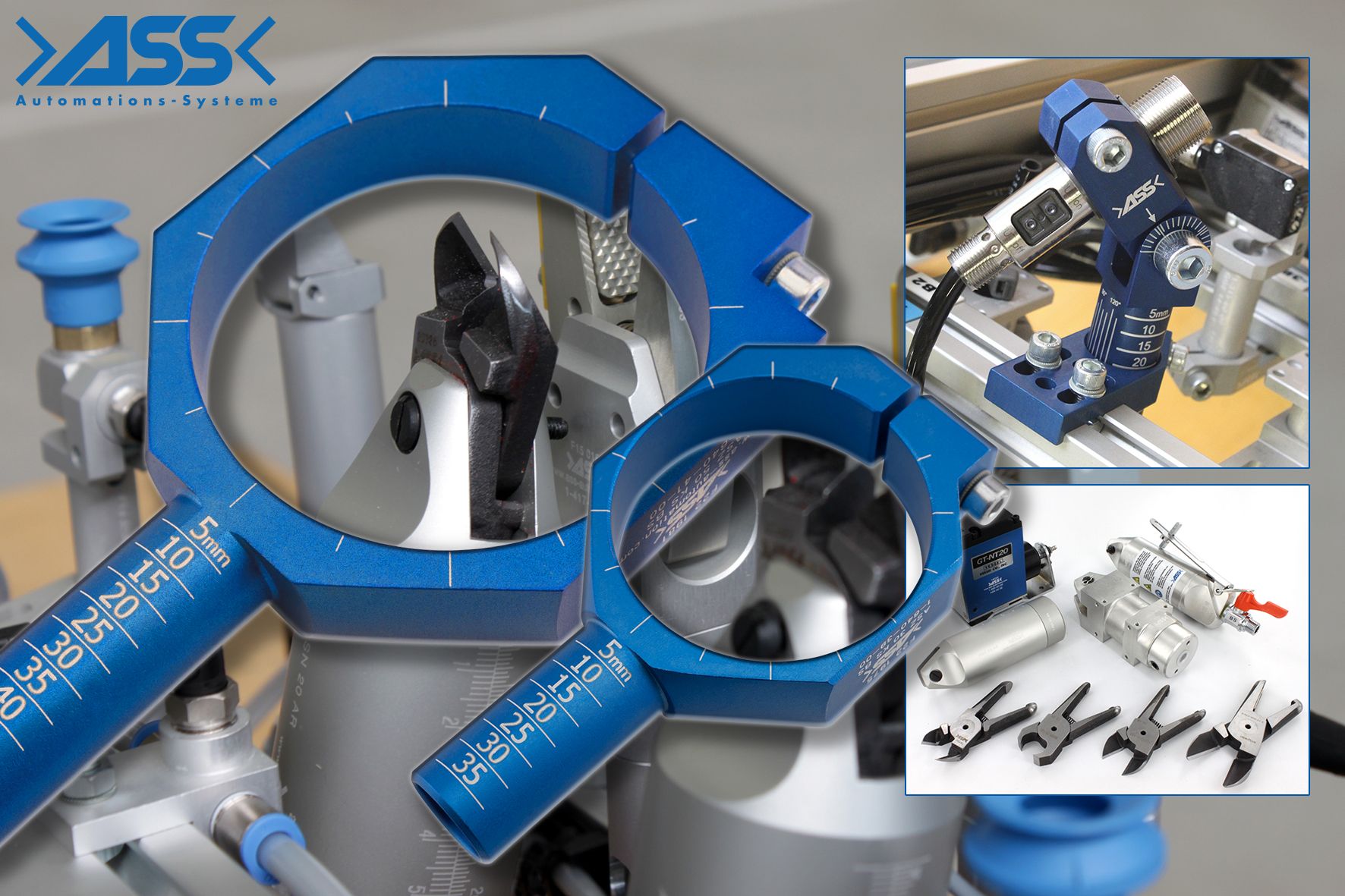

Connection and integration

Our extensive modular system contains numerous cross-system connections to enable you to integrate the components economically and simple.

The large selection of standard parts in the robotic hand kit connects different profiles and components with different clamping diameters with each other and with each other. This ensures that the gripper part required for handling can always be connected in the gripper.

Flexible and easy to use

Semi-automatic quick-change systems and combinable gripping components enable a quick product change within your automation and thus offer a high degree of adaptability to your processes.

The modular system minimizes the set-up and conversion time of a robot gripper (EOAT) through simple components that can also be integrated later.

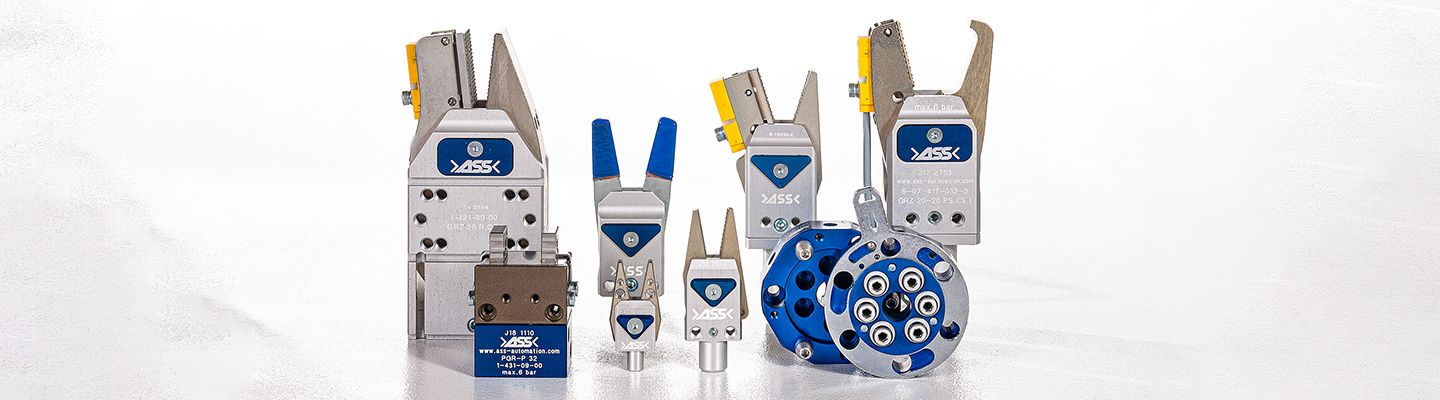

Scalability and variety

The large selection of standardized mechatronic components of different sizes enables a pronounced variety of variants. The spectrum that can be grasped ranges from the smallest plugs to body parts - regardless of the material, be it composite parts made of CFRP, GRP, SMC or other parts made of solid or flexible materials. This variety enables the user to always create a suitable EOAT solution.

Cleanliness and quality

Our low-abrasion mechatronic components can be used in a clean environment without any problems. We offer you technically high-quality, durable and therefore economical components for all areas. In addition to the gripper components, these can also be solutions for testing devices for battery or EOL testing.

Sustainable and deliverability

ASS components are developed, designed and produced at the certified climate-neutral site in Overath and thus make a positive contribution to reducing your CO2 footprint too. The production in Overath enables a rapid reaction to your wishes and our warehouse is a guarantee for deliverability.

More solutions

You can find a comprehensive overview of all the mechatronic components of the ASS Robot Hand Kit (EOAT) with the most important key data such as prices, drawings and dimensions as well as operating instructions for our articles in our online catalogue.