Perfect for the application

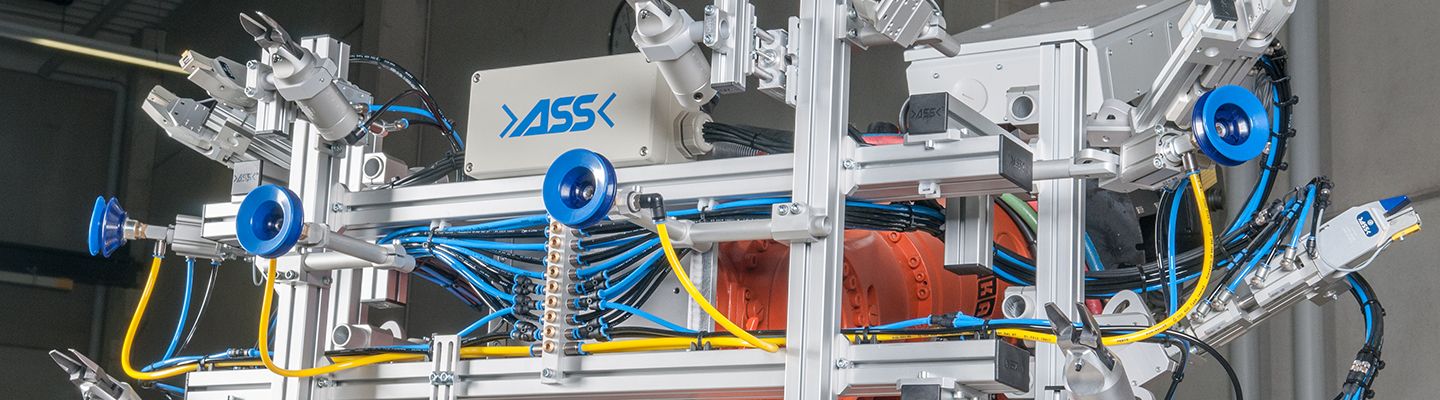

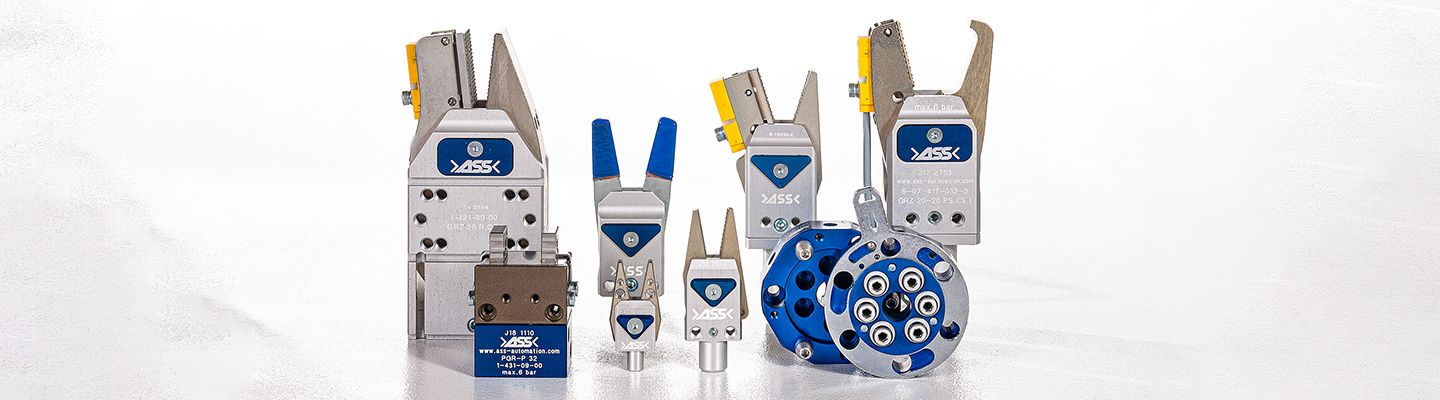

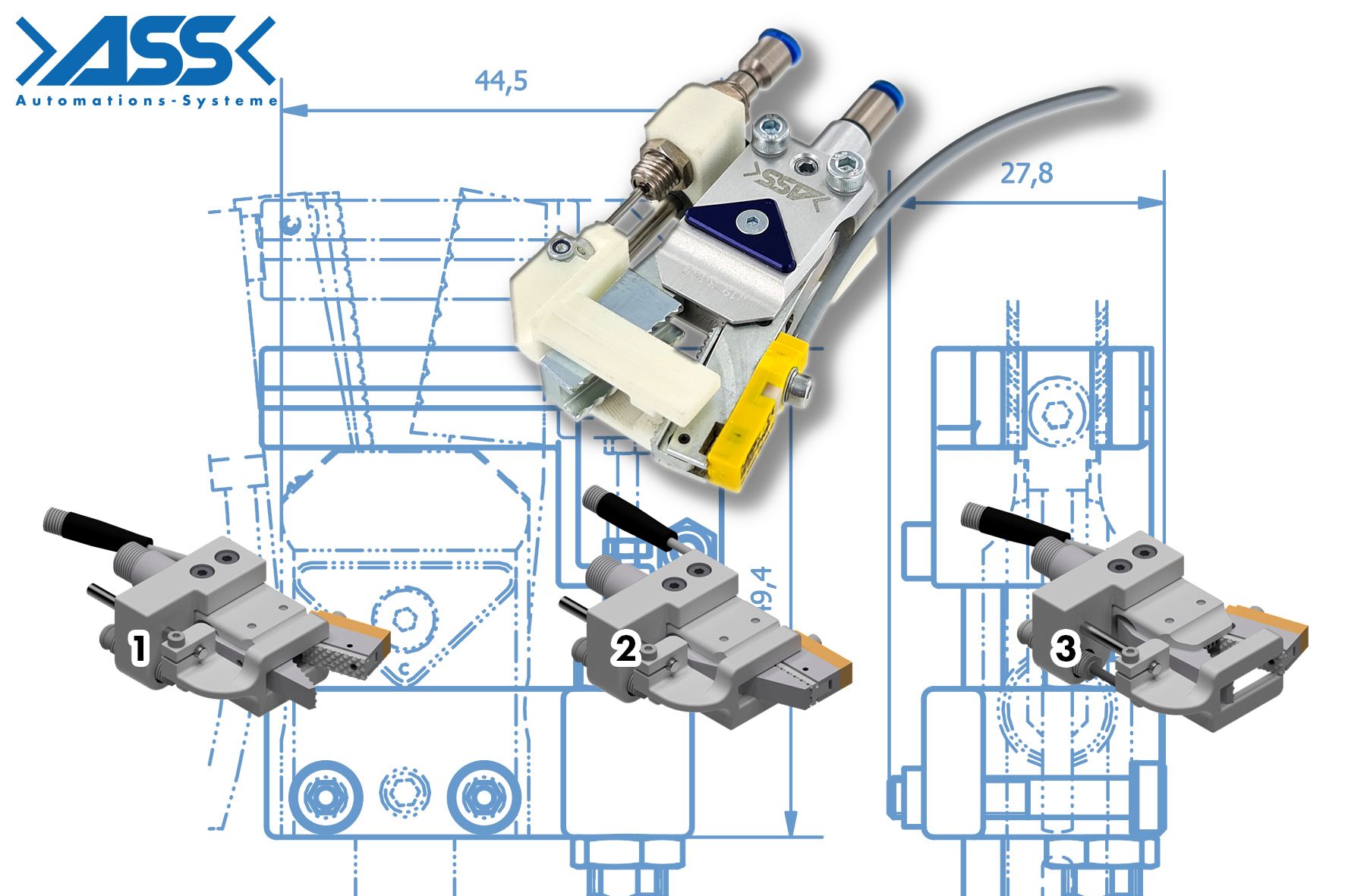

Our gripper parts are used to build robotic hands, often also called grippers or EOAT, for work processes such as separating, gripping, inserting, removing, transferring, trimming, quality testing or, for example, assembly. The robot hand is precisely designed from the more than 2,000 standardized gripper parts available in the warehouse.

Due to the flexibility of the robot hand construction kit, the user has the simple possibility to build robot hands independently or to convert existing grippers. Of course, we also construct and manufacture robotic hands that are precisely tailored to your task.

Robot hands made from standard gripper parts

Robot hands, created from our kit, are used worldwide in a wide variety of industries for automation and handling. The robot hands are used in a wide variety of fully and partially automated industrial processes, such as insertion and removal, assembly or cutting stations, matrix and bumper removal or the handling of limp and tempered lightweight materials.

A guarantee for fast implementation and thus also low downtimes at the customer is the local development and production of our products in Overath, regardless of whether the mechtronic components for your own jig construction are needed or if we create the end-of-arm-tooling d for you.

The grippers and EOAT created from the ASS Robot Hand Kit (EOAT) offer a wide range of applications for a wide variety of industrial areas. The mechatronic gripper parts of the ASS Robot Hand Kit (EOAT) are used, among other things, for grippers and processing stations in the automotive and commercial vehicle industry, including e-mobility, medical, electrical and sanitary engineering or the construction industry. The EC machine directive is taken into account for every robot hand and is accordingly supplied with a declaration of conformity or incorporation. Our quality management is of course certified according to ISO 9001.

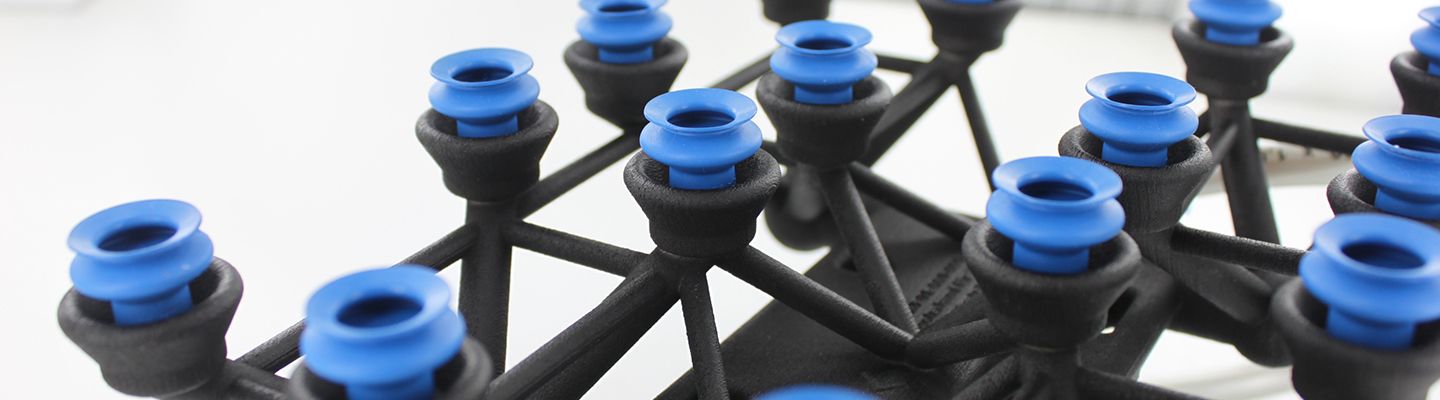

Individual solutions

In addition to standard solutions, we offer special solutions tailored to your application. Special solutions include, for example, 3D-printed gripper jaws and contours or the coating of standard components and contours.

We integrate the special components directly in-house if we carry out the gripper construction, or alternatively we manufacture the special components for you as the user and provide the special components together with the standardized mechatronic components from the ASS Robotic Hand Kit (EOAT) .

The ASS Robotic Hand Kit (EOAT) also includes two other solutions for the basic gripper structure:

Micro System

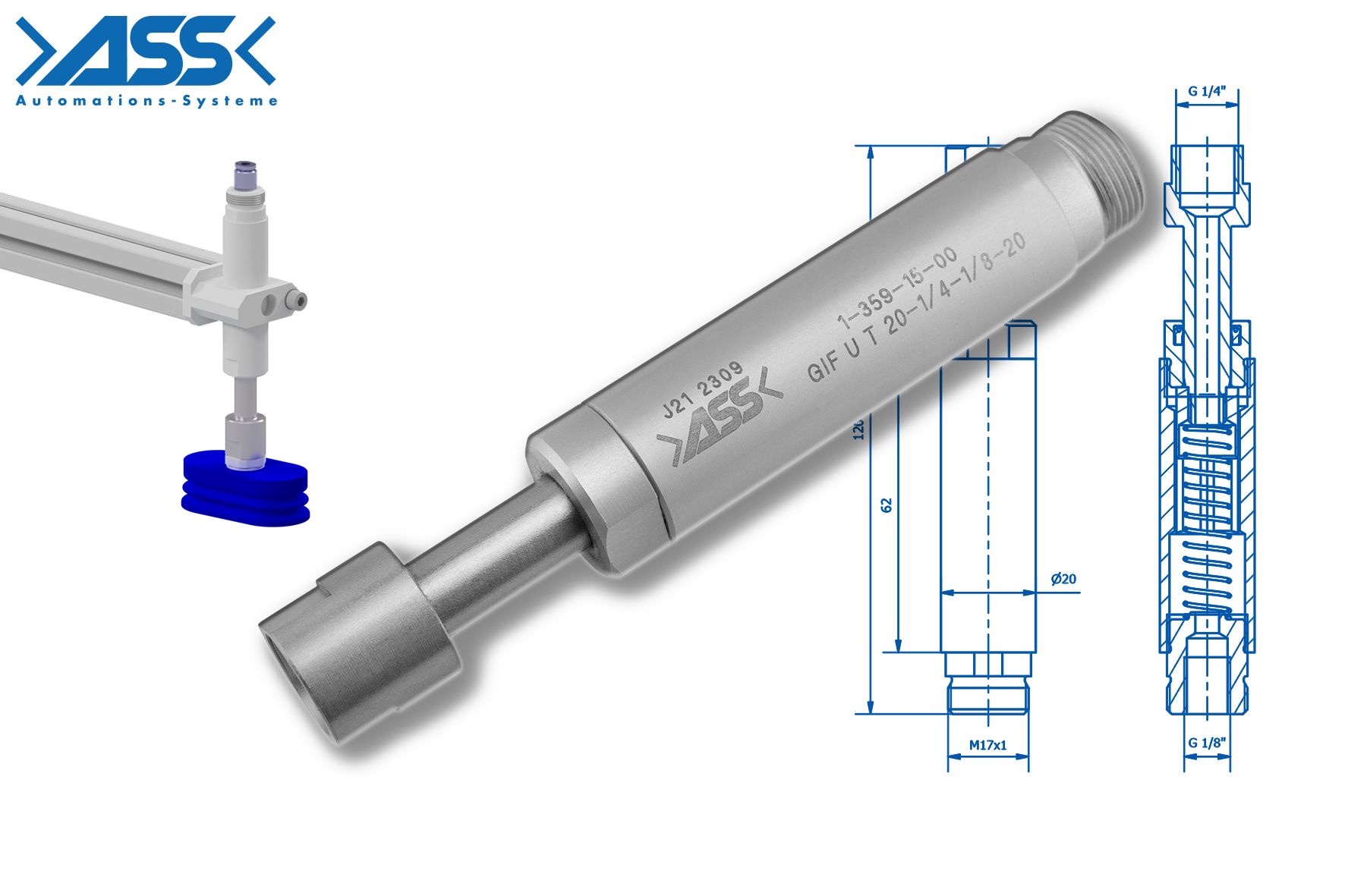

On the one hand, there is the award-winning micro system with a small clamping diameter of six millimeters for the tightest of spaces and tiny components. The Micro System is used where small injection molding machines with limited installation space, linear handling with low load or other small machines are in use and larger and therefore heavier systems reach their limits .

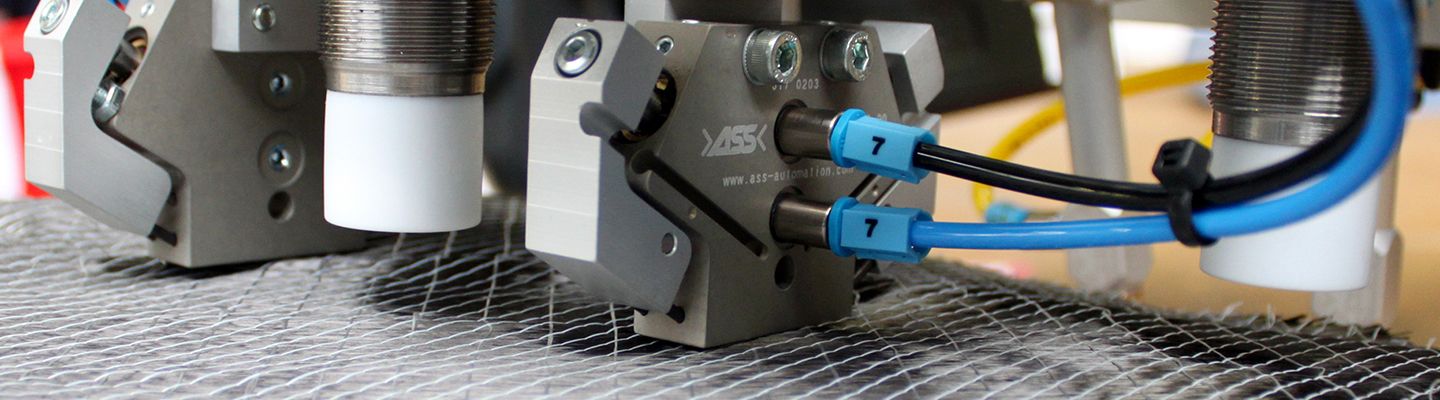

Tubular System

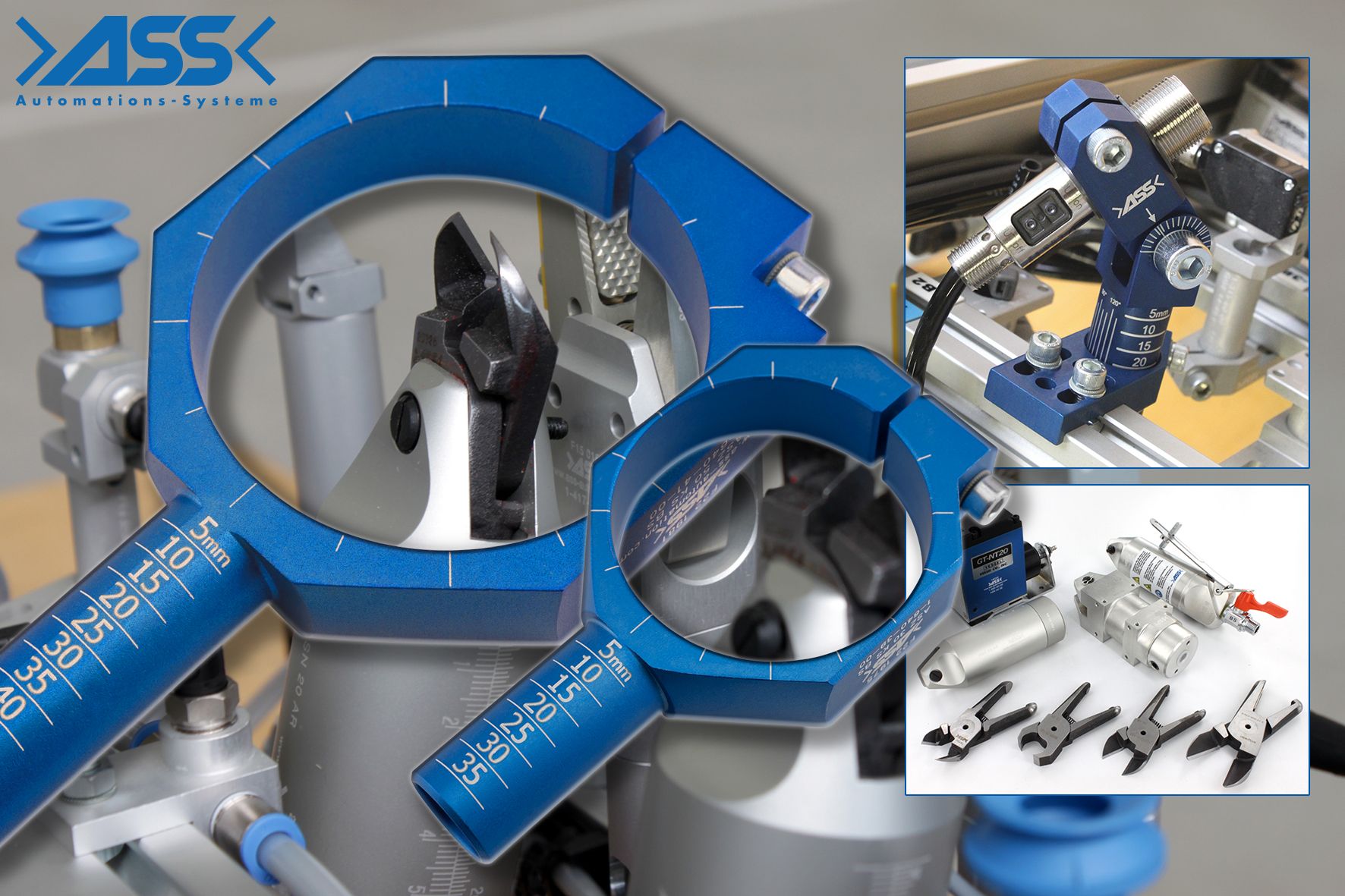

The round tube profile system kit is also included in the robot hand kit. With high-quality, milled connecting elements, round tube grippers can be constructed, among other things for the highest dynamic loads when removing the bumper. The flexible structure of the ASS robot hand construction kit simply integrates the existing gripper parts into a basic gripper structure based on round tubes with just a few usefully added connecting elements. For a simple and replicable setting of position and angle, the clamp combinations can be provided with our "Blue Scale".

ASS Robot Hand Kit (EOAT)

The ASS Robot Hand Kit (EOAT) as the basis for designing and mounting your end-of-arm-tooling consists of over 2,000 standardized mechatronic components that are constantly being expanded and supplemented. As a high-quality and practice-oriented modular system for automation, it offers greatest possible flexibility for gripper construction.