The company ASS Maschinenbau GmbH

ASS Maschinenbau GmbH was founded in 1983 and offers around 120 employees a challenging and attractive job with prospects and topics of the future. ASS serves the gripper parts and EOAT market worldwide and has been served locally by >ASS< End of arm Tooling Inc. located in Plymouth, Michigan. ASS belongs to INDUS Holding AG since 2002.

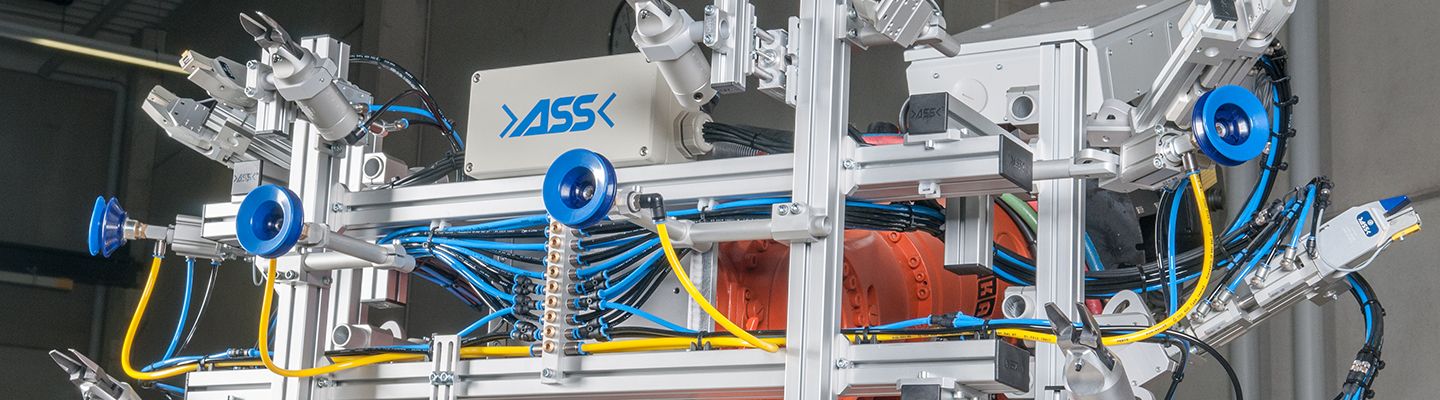

The employees in Overath and partners around the world develop intelligent solutions for various tasks in the fields of automation and robotics. The mechatronic ASS gripper parts are all developed, designed and produced at the certified climate-neutral location in Overath.

The quality management is of course certified according to ISO 9001:2015 and all affected products take into account the EC Machinery Directive.

The product range includes mechatronic gripper parts, robot hands (EOAT), automation systems, 3D printing, FRP handling and ultra-lightweight construction and is rounded off by various services. ASS offers customized solutions for everything to do with injection molding and automation for manufacturers and suppliers in the automotive, e-mobility, lightweight construction and plastic injection molding industries.

Everything from a single source

As a German manufacturer with over 40 years of experience, we supply customer-oriented and high-quality EOAT components or complete solutions. The areas of application range from individual mechatronic components to complete turnkey solutions. This is made possible by the ASS robot hand construction kit, which contains over 2,000 mechatronic components and the supporting over 6,000 special gripper parts. This extensive modular system enables gripping solutions to be adapted to the product areas and production processes of our customers.

ASS automates, among other things, complex work processes in the plastics processing industry and handling solutions for components made of composite materials. Our components and automation systems are used to handle everything from the smallest plastic parts to complex interior and exterior parts.

A lot is also possible in the areas of electromobility. For example, from individual cells to finished battery packs or from small plugs to entire e-charging stations.

As a contact person for your individual tasks, we are at your disposal for a non-binding consultation. Contact us by phone on +49 (0)2206/90547-0 or by email at