Services - From 3D printing to coating

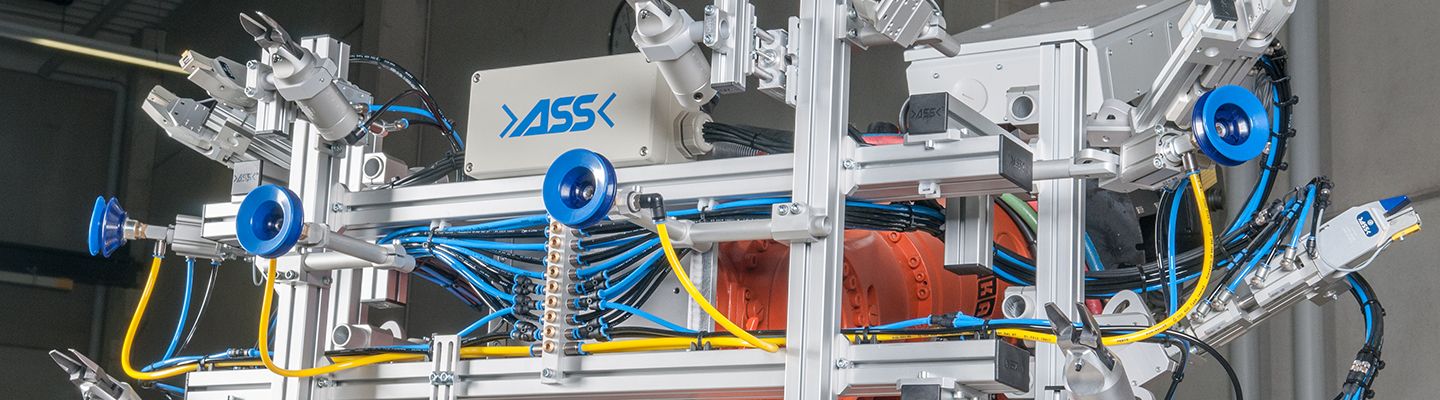

We offer our customers competent service and target-oriented services. From the first idea to the fully automated turnkey solution, we are at your side as an experienced partner.

Therefore, the production including design, control construction, assembly and programming takes place in our house. For maintenance and optimization of your automation technology, we also make our specialists available to you on site. Because for us you as a customer and your requirements for your automation technology are in the foreground. We tailor our services to your needs in a targeted and cross-industry manner. This is how tailor-made products are created with which you can secure the decisive advantage over the competition.

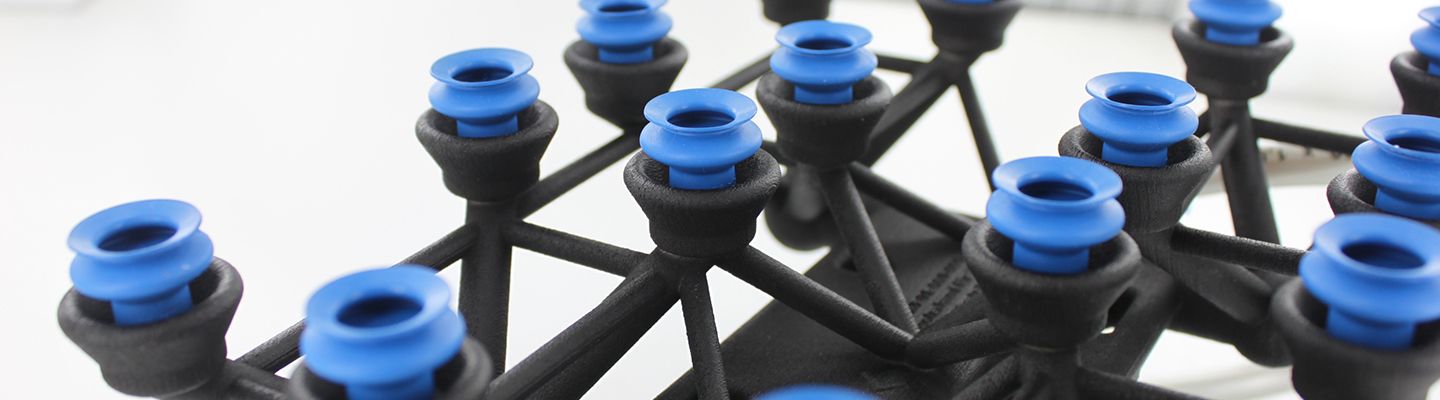

Individual 3D printing

Printed components or entire robot grippers with integrated pneumatics, for example, are used in many areas of automation technology. Whether single runs or series production, we offer both solutions. With neutral or carbon fiber or glass fiber reinforced onyx material or polyamide, we offer different applications for quality solutions with a short-term implementation.

Mark-free and gentle coatings

If required, we coat our components to suit the respective application. It is independent of the material: whether aluminium, 3D-printed polyamide or onyx components or other solid materials.

You can choose from non-stick PTFE or soft flock also our EP coating. The blue, extremely wear-resistant coating with Shore A hardness 90 and the black coating with Shore A hardness 60 are available. The selection of coatings covers numerous applications for sensitive components that are too gentle or mark-neutral in particular components to be painted.

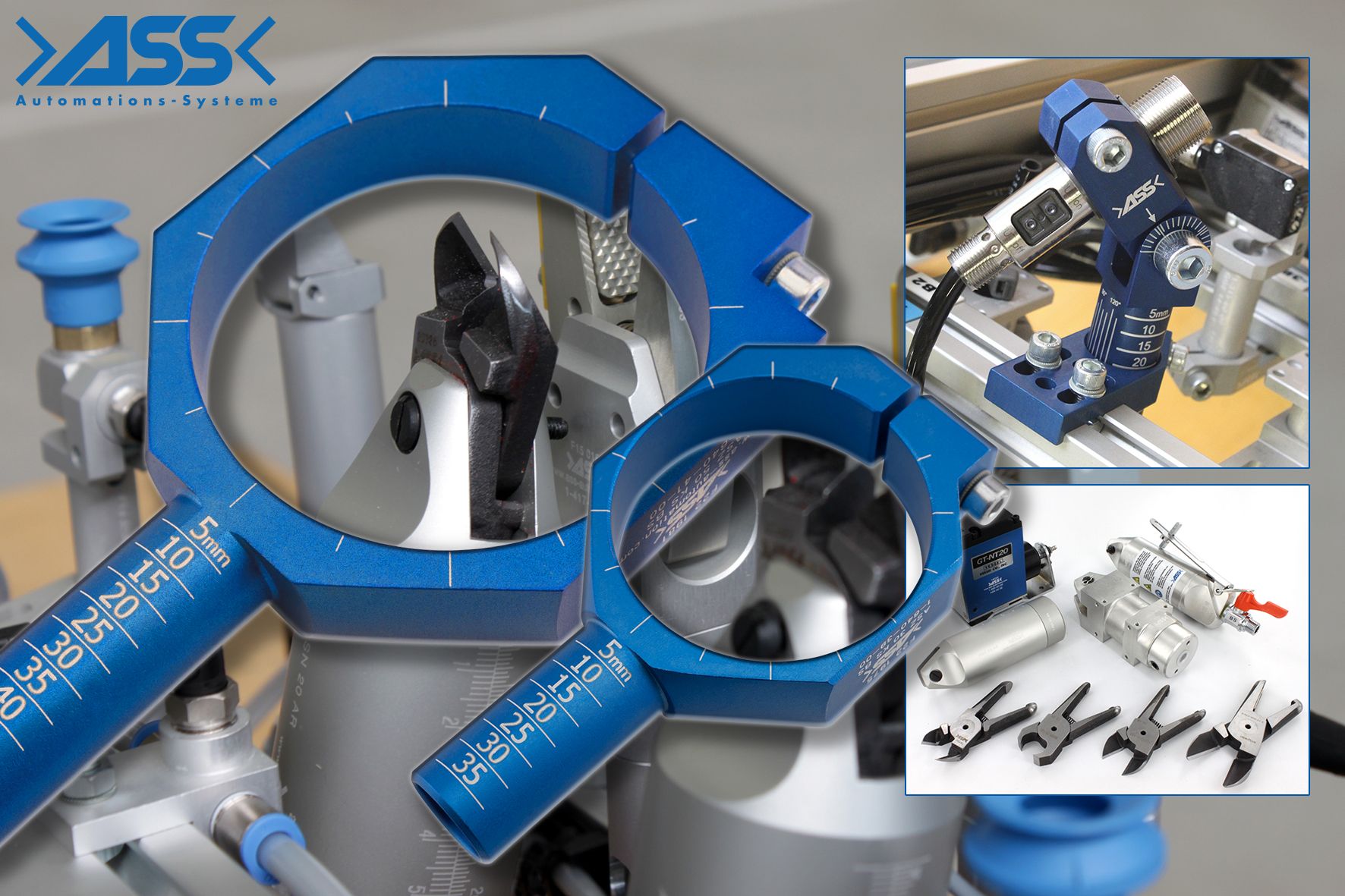

Gripper building training courses

We offer training for our customers and partners and those who want to become one. The training courses are individually adapted to the previous knowledge and countermeasures in the company. As a rule, you bring a sample part with you and after a theoretical introduction we build a corresponding gripper solution together from our components in the robot hand construction kit catalogue.

The training courses can be held at our premises in Overath. Depending on the scope and content, the training courses last one to two days, accommodation is available within walking distance of our location. Alternatively, we can also visit you on site at your company and conduct the training directly on the environment of your machine peripherals.

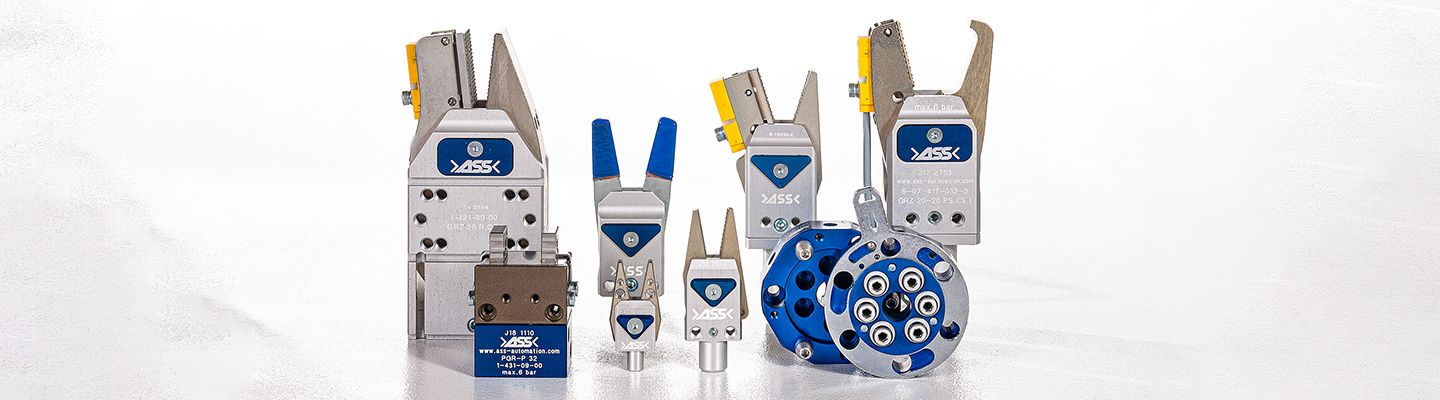

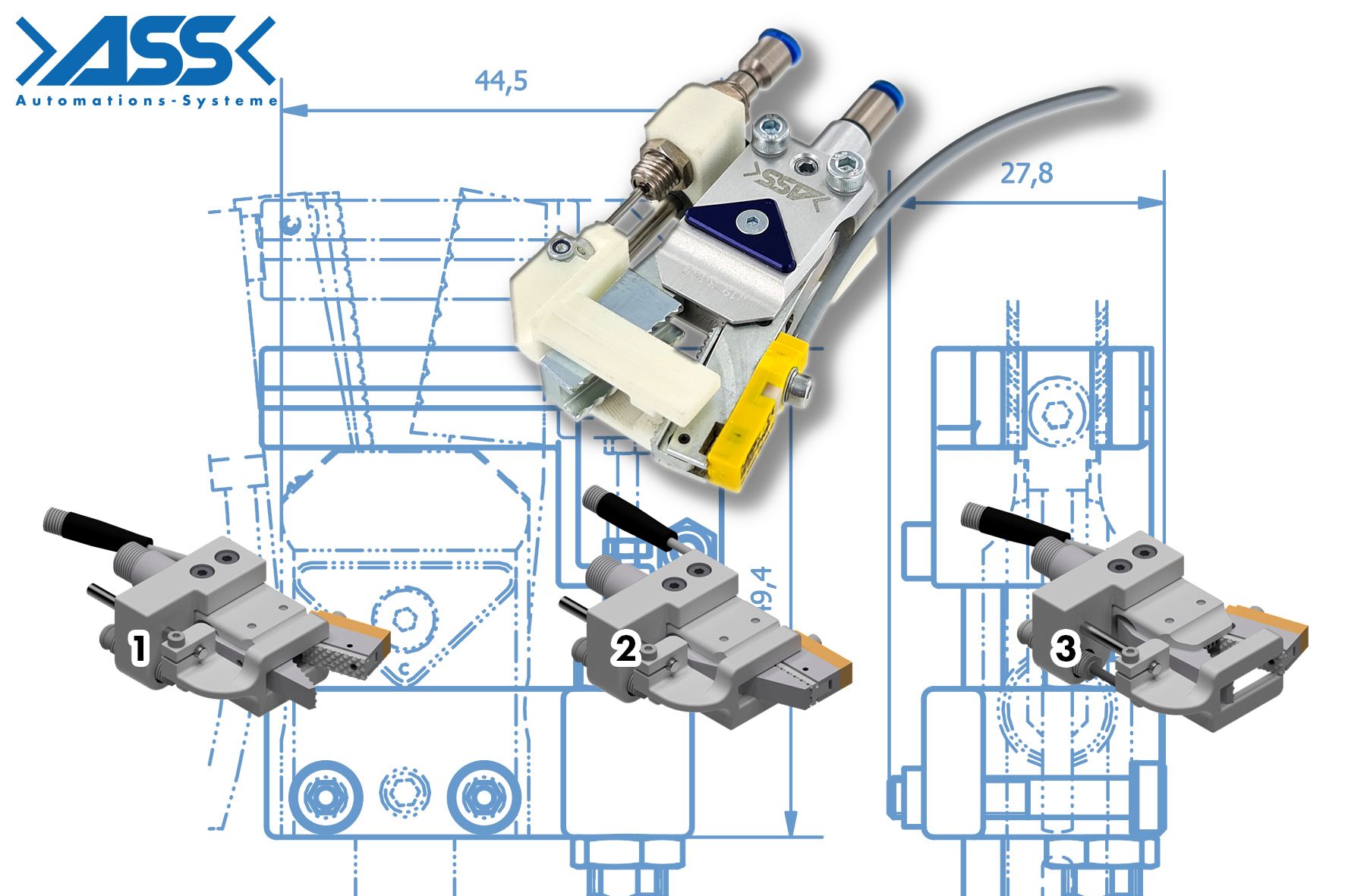

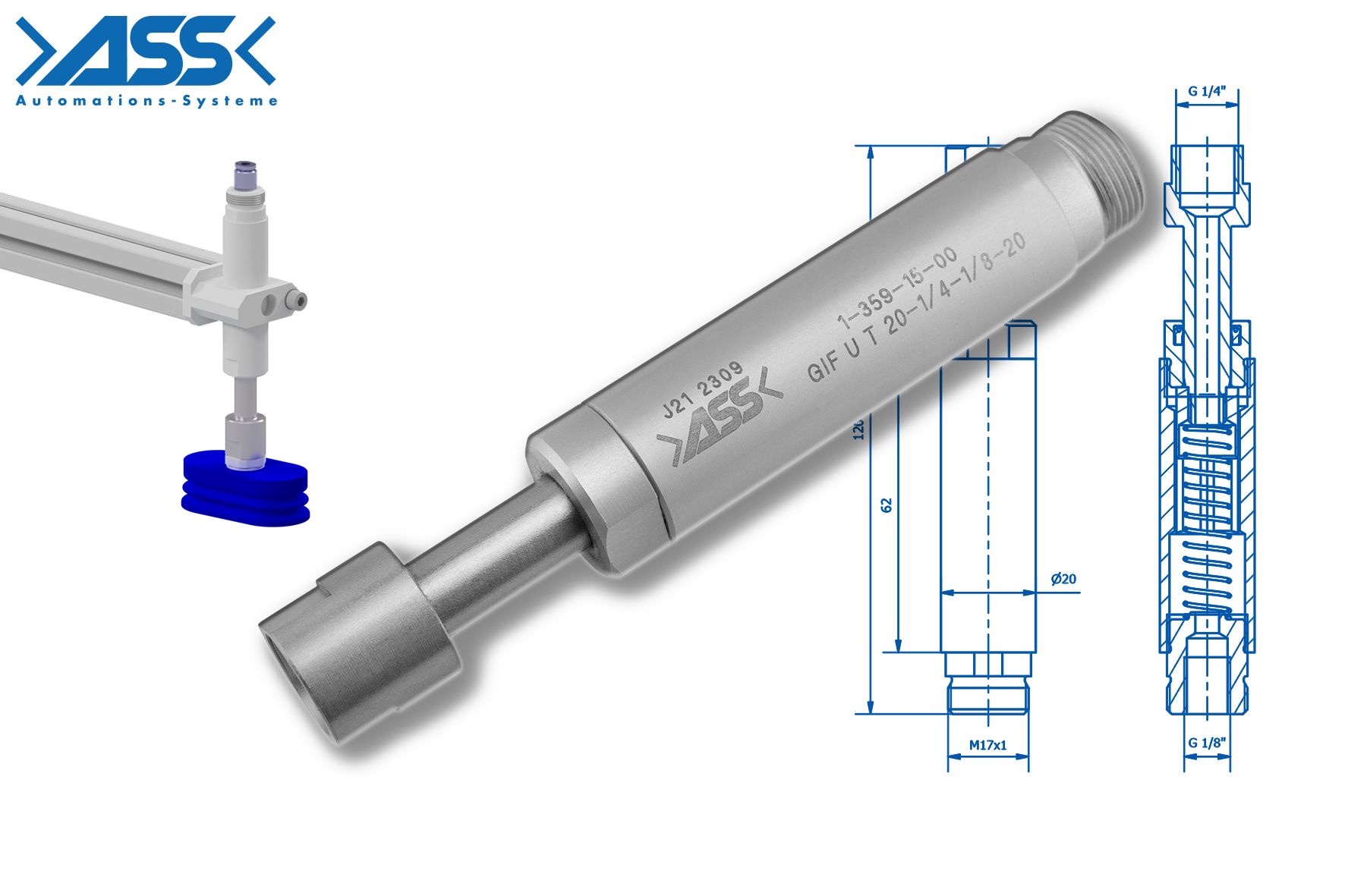

Assembly

As a service, assembly offers the construction of individual gripper parts and robot hands tailored to your requirements. The assembly on site increases the quality and enables quick response times between the customer and ASS. Our reaction time is supported by the direct contact between assembly and the other departments and the high availability of the gripper parts produced on site.

Control construction and programming

As a service, our control engineering department offers not only project planning and hardware planning, but also programming for switching and control systems. Programming for control and robot systems can be carried out in-house or directly on site.

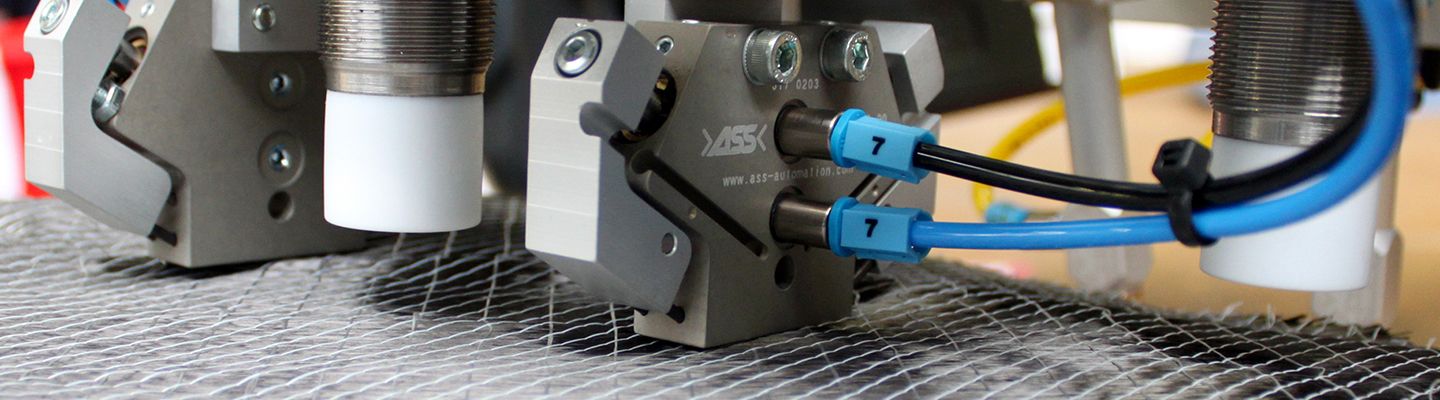

Image processing systems

As a system integrator, we use image processing systems with modern camera technology, optics, lighting and housing to isolate extraneous light. An image processing and quality control system integrated into a manufacturing process, with which the quality, position and alignment of items on a moving conveyor belt are recognized, is a successful example of this.